Boilers are indispensable in industries such as power generation, chemical processing, pharmaceuticals, manufacturing, food and beverages, and refineries. They produce steam and heat essential for numerous applications. However, what

ensures the durability, efficiency, and safety of boilers is the use of refractory materials.

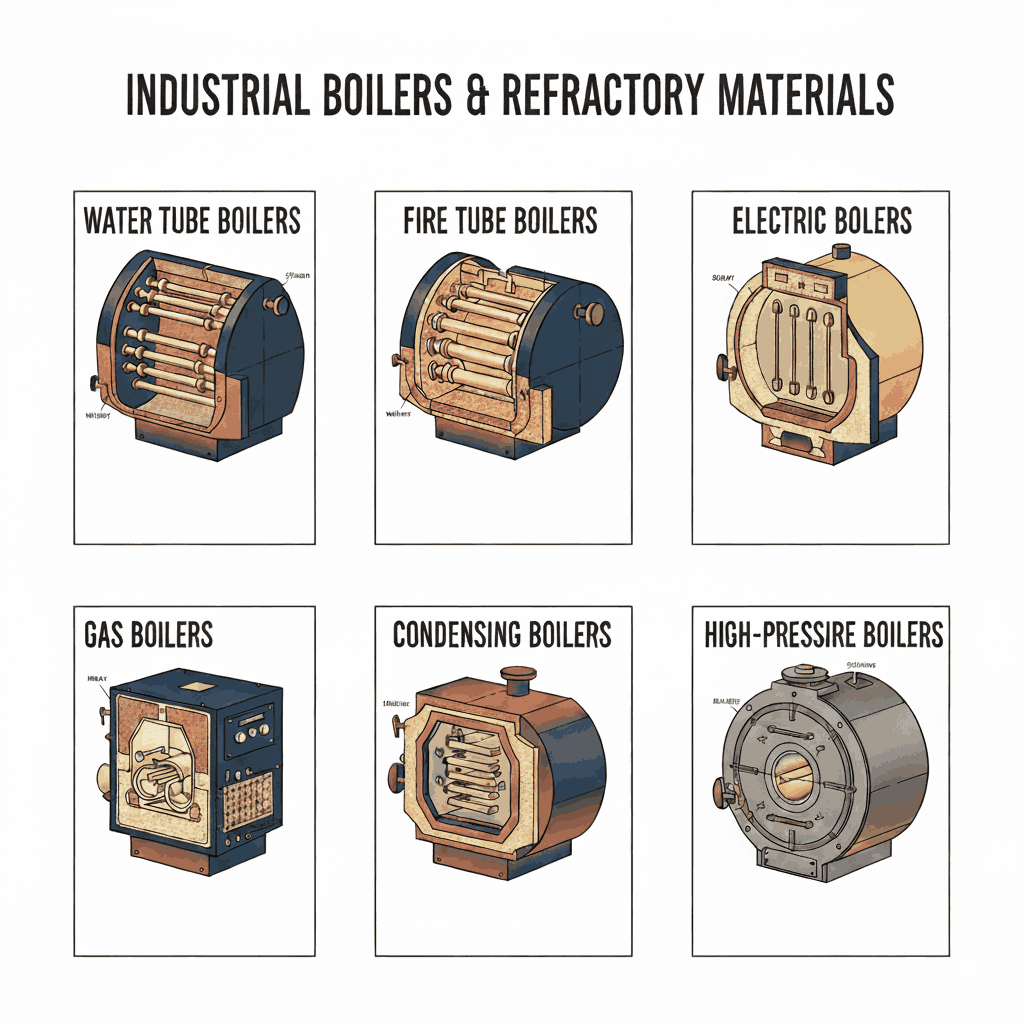

Whether you operate Water Tube Boilers, Fire Tube Boilers, Electric Boilers, Gas Boilers, Oil Boilers, Condensing Boilers, or High-Pressure Boilers, refractory materials are critical. MMP Refratech, a trusted name in the refractory

industry, provides tailored refractory solutions designed to withstand high temperatures, chemical erosion, and mechanical stress, ensuring boilers perform at their peak.

This blog delves into the role of refractory materials in different boiler types and showcases the innovative solutions offered by MMP Refratech to improve boiler performance and lifespan.

What Are Refractory Materials? Why Are They Essential for Boilers?

Refractory materials are specially engineered heat-resistant materials that can withstand extreme temperatures, chemical reactions, and thermal stresses. In boilers, they play a crucial role by:

-

Providing Thermal Insulation: Reducing heat loss to improve boiler efficiency.

-

Protecting Boiler Surfaces: Acting as a shield for metal surfaces against intense heat and chemical corrosion.

-

Enhancing Combustion Efficiency: By optimizing heat retention, they reduce energy and fuel consumption.

-

Ensuring Safety: Protecting critical boiler components from overheating and structural damage.

-

Increasing Longevity: Minimizing wear and tear to extend the boiler’s operational life.

Detailed Applications of Refractory Materials in Various Boiler Types

-

Water Tube Boilers

- Description:Water circulates inside the tubes while hot gases flow around them, making these boilers suitable for high-pressure and large-scale applications.

-

Refractory Applications:

- Furnace Lining: Protects internal surfaces from extreme temperatures using alumina bricks.

- Burner Blocks: Durable blocks that withstand high thermal loads and flame exposure.

- Monolithic Refractories: Ensure a seamless and tight fit for curved surfaces.

- Insulation Boards: Lightweight options to enhance thermal efficiency.

-

Fire Tube Boilers

- Description:Hot gases pass through tubes surrounded by water, ideal for low-to-medium pressure applications.

-

Refractory Applications:

- Refractory Linings for Combustion Chambers: High-strength refractory castables provide insulation and resist cracking.

- Dense Fire Bricks: Offer structural stability in high-heat areas.

- Sealing Mortars: Ensure leak-proof operation and prevent thermal losses.

-

Electric Boilers

- Description:These boilers use electricity to heat water or generate steam, offering an eco-friendly solution.

-

Refractory Applications:

- Support Bricks and Thermal Shields: MMP’s products protect against thermal and electrical wear.

- Low-Density Ceramic Fiber Linings: Lightweight materials to improve thermal efficiency.

- Thermal Insulation Blocks: Reduce energy loss and enhance performance.

-

Gas Boilers

- Description:These boilers burn natural gas, providing energy efficiency and rapid heat generation.

-

Refractory Applications:

- Burner Tile Linings: Withstand the high-intensity flames of gas combustion.

- Ceramic Fiber Modules: Ensure even heat distribution and retention.

- Gas Chamber Linings: Safeguard components from rapid temperature fluctuations.

-

Oil Boilers

- Description:Common in industrial and commercial heating, oil boilers provide powerful heating solutions.

-

Refractory Applications:

- Slag-Resistant Refractories: Protect against residues and corrosion from oil combustion.

- Burner Area Linings: High-strength materials that withstand direct heat from combustion flames.

- Thermal Shock-Resistant Bricks: High-performance castables and insulating bricks prevent heat leakage.

-

Condensing Boilers

- Description:These high-efficiency boilers recover heat from exhaust gases to optimize energy use.

-

Refractory Applications:

- Lightweight Insulation Boards: Maintain efficiency in heat recovery.

- Corrosion-Resistant Refractories: Combat acidic condensation effects.

- Ceramic Fiber Products: Lightweight and durable solutions to enhance insulation.

-

High-Pressure Boilers

- Description:Designed for pressures above 15 psi, these boilers are used in heavy-duty applications like power plants and large-scale industrial operations.

-

Refractory Applications:

- Superheater Linings: Protect areas exposed to extreme temperatures and steam.

- High-Temperature Castables: Ensure durability in areas experiencing intense thermal stress.

- Abrasion-Resistant Refractories: Ideal for zones prone to wear and tear.

MMP Refratech’s Advanced Refractory Products for Boilers

-

MMP Refratech offers a comprehensive range of refractory products specifically designed for boilers:

- High-Alumina Bricks: Provide superior thermal resistance and durability.

- Refractory Castables: Available in low-cement, ultra-low-cement, and conventional options for diverse applications.

- Ceramic Fiber Boards and Blankets: Lightweight and efficient insulation materials.

- Dense Castables: High-strength solutions for high-pressure and high-temperature zones.

- Lightweight Insulating Bricks: Reduce heat loss while maintaining structural integrity.

- Monolithic Refractories: Seamless application for curved and irregular surfaces.

- Refractory Mortars and Sealants: Ensure tight sealing and easy application.

Industries Benefiting from MMP Refratech’s Boiler Refractory Materials

- Power Generation: Boilers in power plants require high-strength refractories for consistent performance.

- Chemical and Petrochemical Processing: Reliable linings for oil and gas boilers in harsh environments.

- Food and Beverage: Energy-efficient refractory solutions for fire tube and condensing boilers.

- Pharmaceuticals: Precision-engineered materials for controlled heating in electric and gas boilers.

- Steel and Cement Plants: High-pressure and water tube boilers require abrasion-resistant linings.

- Refineries: Oil boilers equipped with corrosion-resistant materials to handle extreme conditions.

Why Choose MMP Refratech for Boiler Refractory Needs?

-

- Tailor-Made Solutions: Customized products to meet the specific requirements of every boiler type.

- Unmatched Quality: High-grade materials designed for durability and efficiency.

- Energy Efficiency: Reducing heat loss and optimizing fuel consumption.

- Eco-Friendly Practices: Refractories designed with sustainability in mind.

- Technical Expertise: Expert support for installation and maintenance.

Conclusion:

Refractory materials are vital for the safe, efficient, and long-lasting operation of boilers. At MMP Refratech, we deliver cutting-edge refractory solutions tailored for a wide range of boiler applications. Our expertise ensures that industries worldwide achieve optimal performance, energy efficiency, and cost savings.

To learn more about how MMP Refratech can enhance your boiler operations, visit MMP Refratech today. Partner with us for unmatched reliability and efficiency in your industrial processes.